Technology

Investment on cutting-edge technologies that allow for ongoing improvements in regards to quality and efficiency of its work is Engetower’s primary guideline. On that purpose, the company develops its own innovative solutions for all design development stages such as advanced software for structural analysis and tridimensional detailing, 3D visualization systems compatible to virtual and increased reality devices and the use of Artificial Intelligence techniques and resources.

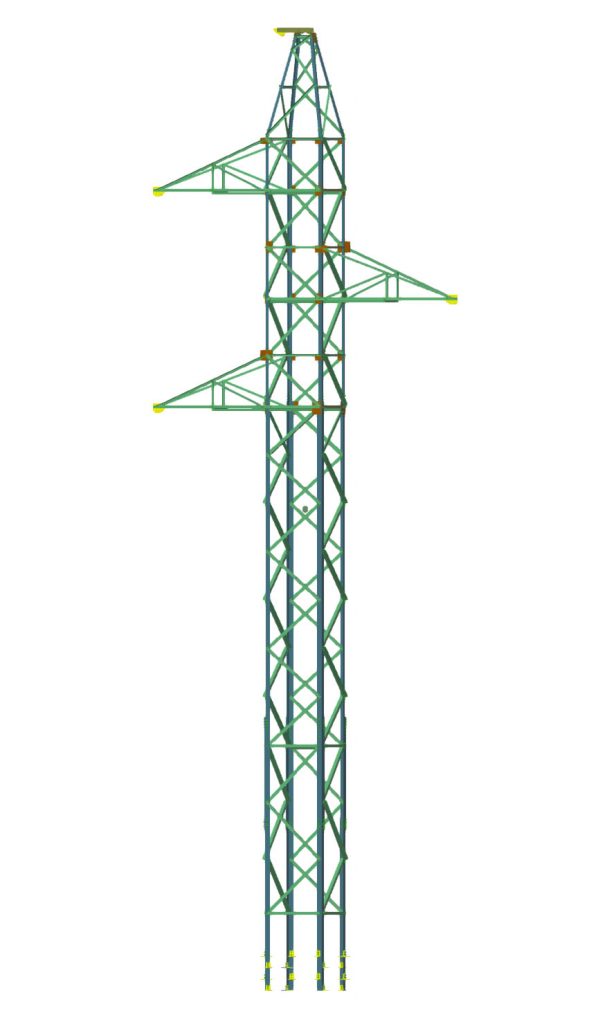

TRUSSPOLE®

Practicality for distribution

Developed by Engetower, Trusspole® is a practical and safe latticed pole that uses one single metal or concrete (with stubs) foundation per structure. The choice depends on the project aspects such as location, kind of soil and construction costs.

Visually similar to the structure of the conventional pole, Trusspole® differs for being a slim light structure with low visual impact and that is easy to manufacture, transport, store and assembly. Compared to the traditional structure (four-legged pyramidal trunk tower), Trusspole® is advantageous for reducing the weight of the structure and the volume of excavation and foundation backfill, factors that contribute for agility and economy in the implementation of low-voltage lines (up to 138 kV).

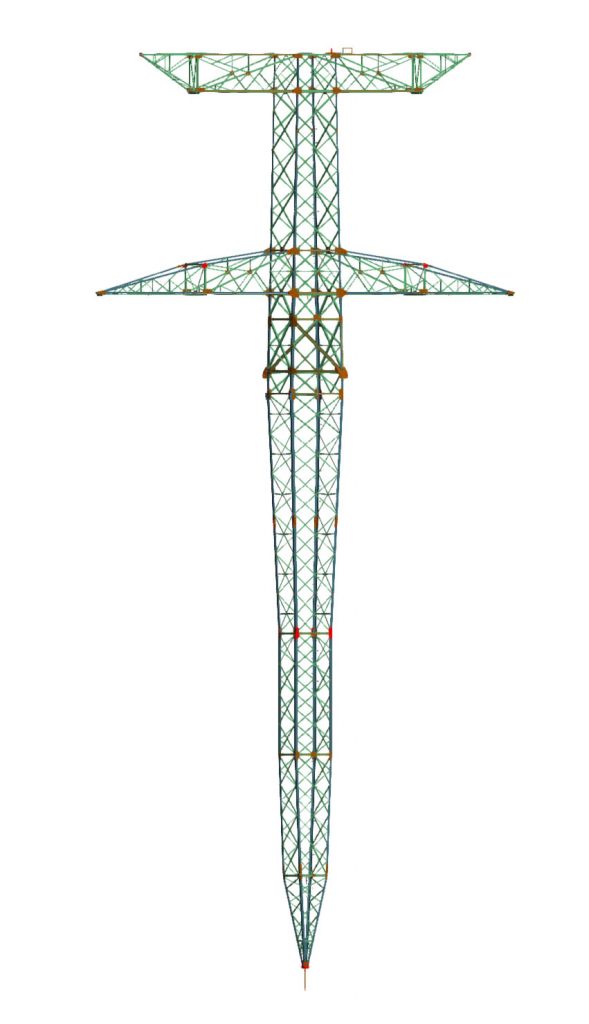

MONOMAST

Economy for transmission

Engetower was a pioneer in incorporating technological innovations into the latticed monomast solution. With technological resources and the experience of its team, it developed the Cat-Face Monomast (3I®) structure for single circuits and the Danube Monomast structure for double circuits. Those new solutions have been allowing for the implementation of transmission lines with reduced construction timeframes and significant economic results.

Cat-Face Monomast 3I® is structurally similar to the V and the Cross-Rope latticed towers. It features the possibility of enlarging spans and cable/ground working heights with no significant weight increases. As a result, more economic transmission lines with average span around 500m (2 structures/km) are obtained.

The Danube Monomast latticed tower provides for more agility and economy in the construction of double circuit transmission lines, which were previously built by using self-supporting towers (about 40% heavier).

Under the constructive standpoint, the Cat-Face Monomast 3I® and the Danube Monomast towers can be easily assembled by means of both manual and mechanized processes. They may also be lifted in the vertical after horizontal pre-assembly. Additionally, structure assembly is made easier by the fact that it has a single mast in which the guy lines can definitely be installed even before the head is assembled. The use of temporary guy lines is not necessary.

ENGETOWER IN THE 4.0 INDUSTRY AGE

Engetower continuously develops its internal processes so as to establish the appropriate technological and organizational infrastructure for the complete adoption of the BIM and IoT (Internet of Things) concepts in accord with the 4.0 Industry guidelines.

Through the extensive work of a multidisciplinary team consisting of engineers, designers and developers, proprietary software for structural analysis and 3D modeling was developed to work in a fully integrated way, which allows for a more agile and accurate structure calculation and detailing process. The complete 3D structure modeling also enables the direct generation of fabrication sheets for CNC machines (CAM files), which dispenses the need for fabrication drawings that become optional for the client.

All that innovative process provides manufacturers and assemblers with access to a 3D part visualization system to be entered into through mobile devices such as tablets, smartphones and notebooks. By using that system, it is possible to interact with the tridimensional model corresponding to the structure in order to view and print design documents such as drawings, material take-offs etc.

Engetower’s experience demonstrates that this new integrated digital information system results in significant and measurable increase to efficiency, quality control and cost reduction for all design, fabrication and assembly stages related to transmission line structures.